- Home

- Spande S5 – Mid-Web Flexo Press

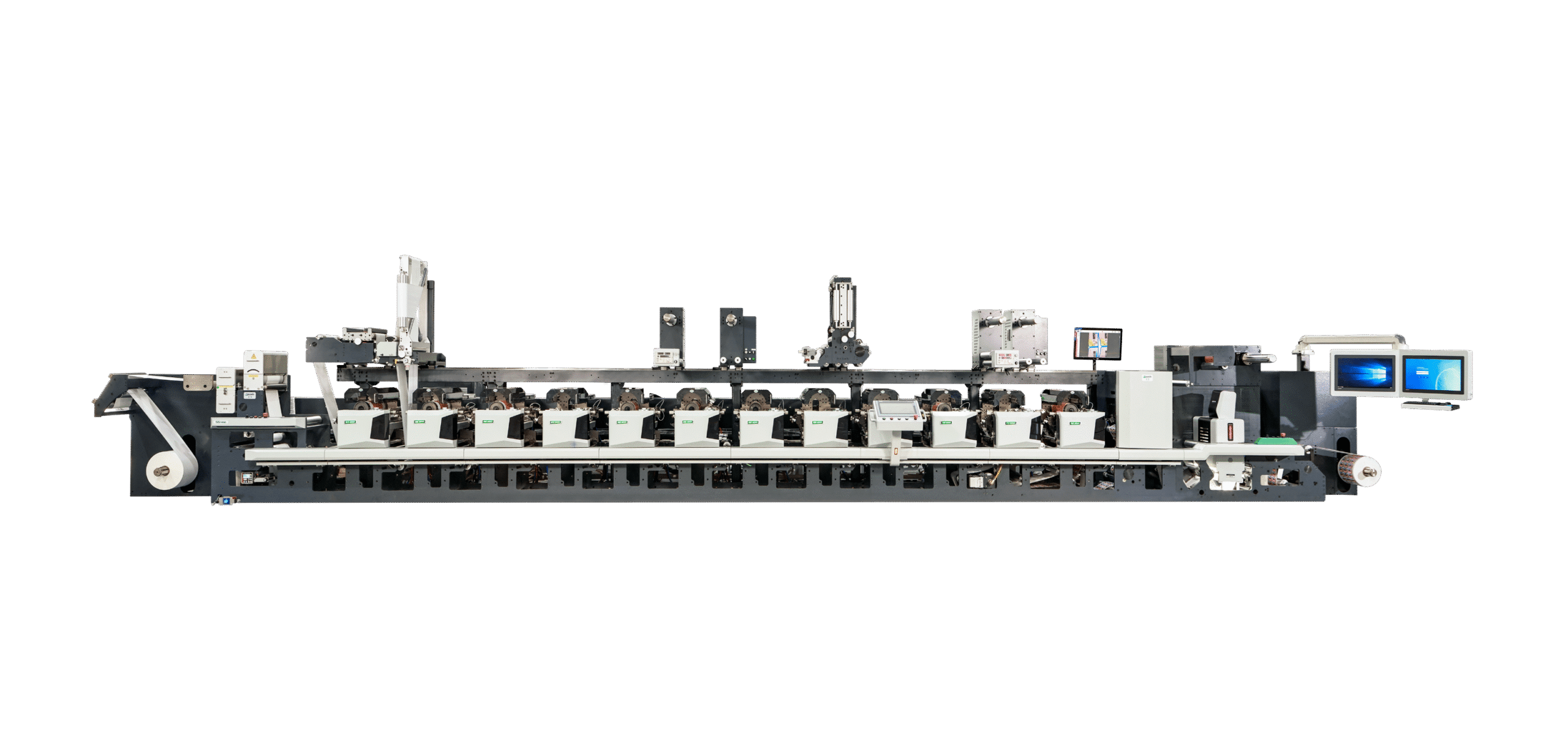

Spande S5 – Mid-Web Flexo Press

Productivity, precision, and flexibility for label and packaging printing

Presentation

The S5 is designed as an affordable, high-performance solution for mid-end and growing label converters. It delivers an excellent cost-to-performance ratio while ensuring high-quality output across a wide range of substrates.

The press supports label and flexible packaging applications on materials from 12–300 microns, with web widths of 370 mm, 450 mm, and 520 mm. Printing repeat is 78–192 teeth, with a maximum speed of 200 m/min. Each station integrates four independent servo motors for easy operation, robust performance, and very short web paths.

Key Innovations & Advantages

- Independent servo drive for printing cylinder, anilox, and anvil roller → precision without gears, ideal for sensitive substrates.

- Servo-driven die cutting with pneumatic-hydraulic pressure system → no manual adjustment, precise and stable cutting.

- Optimized matrix stripping with motorized support → stable for small & special-shaped labels.

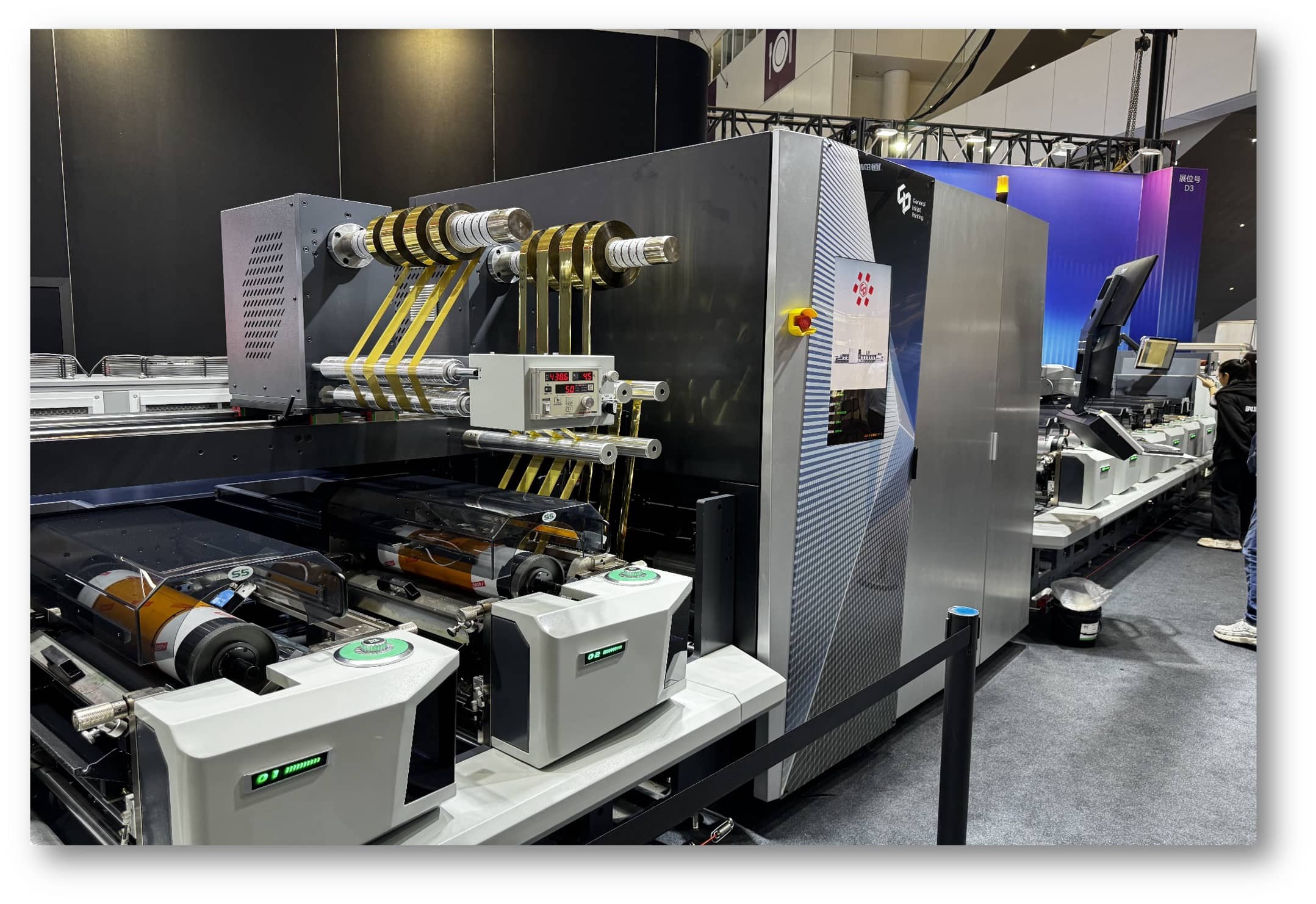

- Modular inline flexibility: Cold foil, Lamination, De/Relam, Turning bar, Multilayers, Screen, Hot stamping, Inkjet, Rotogravure, etc.

- Compact design → quick job changes, minimal waste.

Technical Specifications

- Max Printing Speed: 200 m/min

- Substrate Range: 12 – 300 microns

- Printing Widths: 365 / 445 / 515 mm

- Max Web Width: 370 / 450 / 520 mm

- Printing Repeat Range: 78 – 192 teeth

- Unwinder Max Diameter: 1000 mm

- Rewinder Max Diameter: 1000 mm

- Max Tension: 30 kg (higher on request)

- Registration Accuracy: ±0.1 mm

- Cross Register Movement: Motorized

- Printing Plate: Plate on shaft (no gears)

- Print Shaft Drive: Independent servo

- Anilox Roller: Independent servo

- Anvil Roller: Independent servo, cooled

- Registration Control: Electronic (Option: M-track)

- Die Cutting Pressure Control: Manual / Pneumatic-hydraulic

Conclusion

The Spande S5 is more than a mid-web flexographic press: it is a strategic tool for printers seeking to combine productivity, quality, and flexibility.

With its high level of automation and modularity, it stands as a must-have choice for the demanding label and packaging markets.