- Home

- SMAG – Converting Equipment

SMAG – Converting Equipment

iconvert ICON multi-process platform for post-print digital finishing and converting, and production of logistics-type labels + A4 sheets

The ICONVERT is part of the ICON multi-process platform for label converting and is integrating a wide choice of fully servo-driven printing and converting modules.

The ICONVERT line is dedicated to post digital printing finishing (including Flexo printing, cold foil stamping, laminating, die-cutting, etc.), and can work off-line or in-line (via a synchronization module). The ICONVERT line is infinitely combinable, for solutions tailored to every market application. The platform is also modular and compatible by retrofit with all modules in the ICONCEPT range (such as Hot Stamping and Screen-Printing stations) and ICONTROL (control section).

It is also used as a flexographic printing and die-cutting machine (multi-station for top and bottom die-cutting, sheet-fed die-cutting) for the logistics and A4 board markets… It can integrate up to 4 flexographic printing units and 4 die-cutting units. Other modules in the range can be connected, such as non-stop rewinders, sheeting, stackers…

Converting and finishing processes

- Compact or large unwinders with 3 available diameters (850 / 1000 / 1200) mm.

- Pre-equipment on unwinder to receive corona treatment and web cleaner.

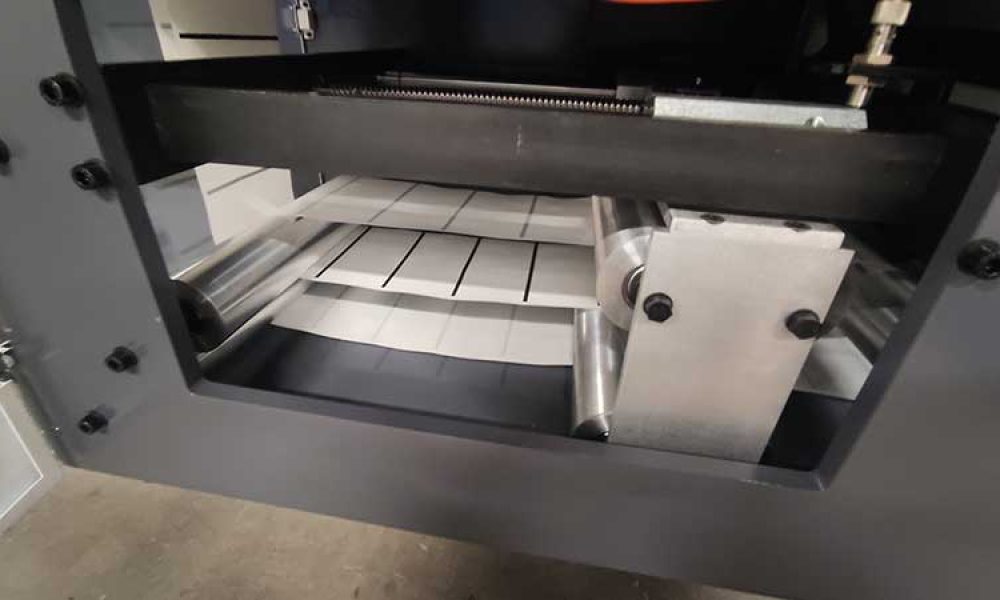

- Die cutting unit in servo-rotary and semi-rotary versions, or DGV-type flatbed.

- Waste matrix with pressure arm and Snowball system.

- Visualization, 100% inspection and control module with a wide range of cameras available.

- Wide choice of slitting units with interchangeable cassette for shear knives or razors, pressure knives, underscoring, or shear knives with automatic positioning.

- 1 or 2-shaft rewinders for simultaneous or alternating rewinding of finished products.

- Semi-automatic rewinder with 2-shafts.

- Non-stop 2-shafts rewinder with automatic gluing system.

- Sheet delivery with conveyor.

Printing and converting processes

- Flexo units available in mechanical rotary, rotary servo or semi-rotary servo versions with UV / LED / hot air / IR drying systems.

- Delam / relam for flexo unit for printing on glue.

- Laminating and cold foil stamping.

- Lamination mounted on a rail.

- Inkjet printing for variable printing.

- Applications modules for coupon labels, booklets and labels dispensing.

- Parts removing system.

Compact line for post-printing converting and finishing

The ICONVERT • LITE is the ideal compact solution for pre-printed labels. ICONVERT • LITE dedicated to labels die cutting and finishing.

The machine can receive as option web treatment systems, full varnish module and laminating or cold foil system.

Converting and finishing processes

- Compact unwinder with predisposition for corona treatment.

- Servo-rotary and semi-rotary cutting station.

Pressure gauge manometer in standard. - Optional gap adjustment system.

- Waste matrix with pressure arm.

- Razor blade slitting unit.

- 1 or 2-shaft rewinders for simultaneous or alternating rewinding of finished products,

Printing processes and added value (options)

- Flexo units available in mechanical rotary, servo rotary or semi-rotary servo versions.

- UV / LED drying systems for the flexo station.

- Laminating and cold foil.

- Snow ball waste rewinder.

- Semi automatic turret rewinder.

Multi-process platform for inspection and reconditioning

The ICONTROL line is dedicated to the control, inspection and finishing of labels and flexible packaging. The ICONTROL line integrates a wide variety of modules from the ICON platform.

The ICONTROL line is infinitely combinable, for tailored solutions to every market application. This platform is also modular and compatible with all ICONCEPT and ICONVERT modules.

Converting and finishing processes

- Compact or large unwinders with 3 available diameters (850 / 1000 / 1200mm) with ultrasonic web guide.

- Wide choice of slitting units with interchangeable cassette for shear knives or razors, pressure knives, underscoring, or shear knives with automatic positioning.

- Single and dual shaft rewinders for simultaneous or alternating rewinding of finished products.

- Semi-automatic rewinder with 2-shafts.

100% control and inspection options

- From simple visual inspection with cells to 100% camera inspection…

- Splice detection and flag detection.

- Visualization, inspection and control module.

- Includes a second inspection table equipped with 2 pneumatic clamps and a trash rewind shaft.

- 100% inspection by BST Nyquist or EL camera (or other models), for control of printing, color variation, variable data…

Variable data printing options

- Double-sided printing, marking and numbering modules.

- Inkjet printing modules with UV or LED curing.

Inspection Rewinder

(C4R+)

The Icontrol Lite (also named C4R+) is a Inspection slitter rewinder and offer the following features :

- Slit with large choice of slitting solutions.

- Inspect, by using cells or 100% inspection camera, and stop

defects on a splicing table. - Rewind rolls, on a single shaft, dual shafts or with a semi automatic turret rewinder, with a pre-selected length or number of labels.

Multi-functional label die cutting machine

D (COMET +)

The Icontrol lite D (COMET+) offers multiple functions:

- Inspection rewinder with rotary die-cutting station(s)

(from 1 to 3 die-cutting stations). - Printing via rotary flexo station(s), label die-cutting and converting (reel-to-reel or reel-to-sheet).

Each machine configuration is available in two widths, 350 mm and 420 mm, and is also completely modular and upgradeable.

Inspection rewinder machine

CLASSIC

NEPTUNE

The NEPTUNE is a Inspection slitter rewinder in seated working position.

- Slit and vacuum the edges,

- Inspect, by using cells or 100% inspection camera, and stop defects on a splicing table,

- Rewind rolls of pre-selected length or number of labels onto a shaft.

Digital Braille printing and converting solution

CLASSIC

VEGA Braille Icontrol lite Braille

Basic principles of Braille

- Developed in 1825 by the Frenchman Louis Braille

- 6 dots, arranged in two columns of three dots

Some differences between the individual national languages - Experienced readers can read 100 words per minute, readers who can see about 250 to 300 words per minute.

EN 15823 as recommendation for the pharmaceutical and packaging industries

Principles of the Vega Braille developed with HHS Baumer technology XTEND 3

Principle of operation

- By means of head equipped with 6 electrically actuated valves, a low viscosity UV varnish is applied in dot form and raised on a substrate and subsequently cured.

- Each printing head can print 2 lines of Braille simultaneously, typeface Marburg Medium

- Application head can be temperature-controlled in order to regulate the varnish viscosity and keep it constant

UV varnish

- The UV varnish hardens by means of a chemical reaction (polymerization), excited by a UV lamp, to form a hard film.

- A servo compensation trolley, during the machine stop process, will pool the web back and forward under the UV section in order to have no waste.

Advantages

- Print on demand, no artwork or tooling

- Integrate software

- Fast Set up time and no waste…

Servo compact multi-function rewinder

CLASSIC

VEGA gen. II : Icontrol lite type V

The Vega offers, among others, the following:

- Unwind and rewind from right to left, and vice versa, in and out (reversible direction of the mandrels),

- Preset batch and total count,, thus subdividing a master reel into reels.

- 100% camera inspection. If a fault is detected, VEGA II automatically stops the machine on the inspection table,

- Step-by-step operation for inspection, encoding and other applications,

- Integration of inkjet, digital and Braille printing solutions…