- Home

- LUSTER

Range of Luster Solutions and Equipment

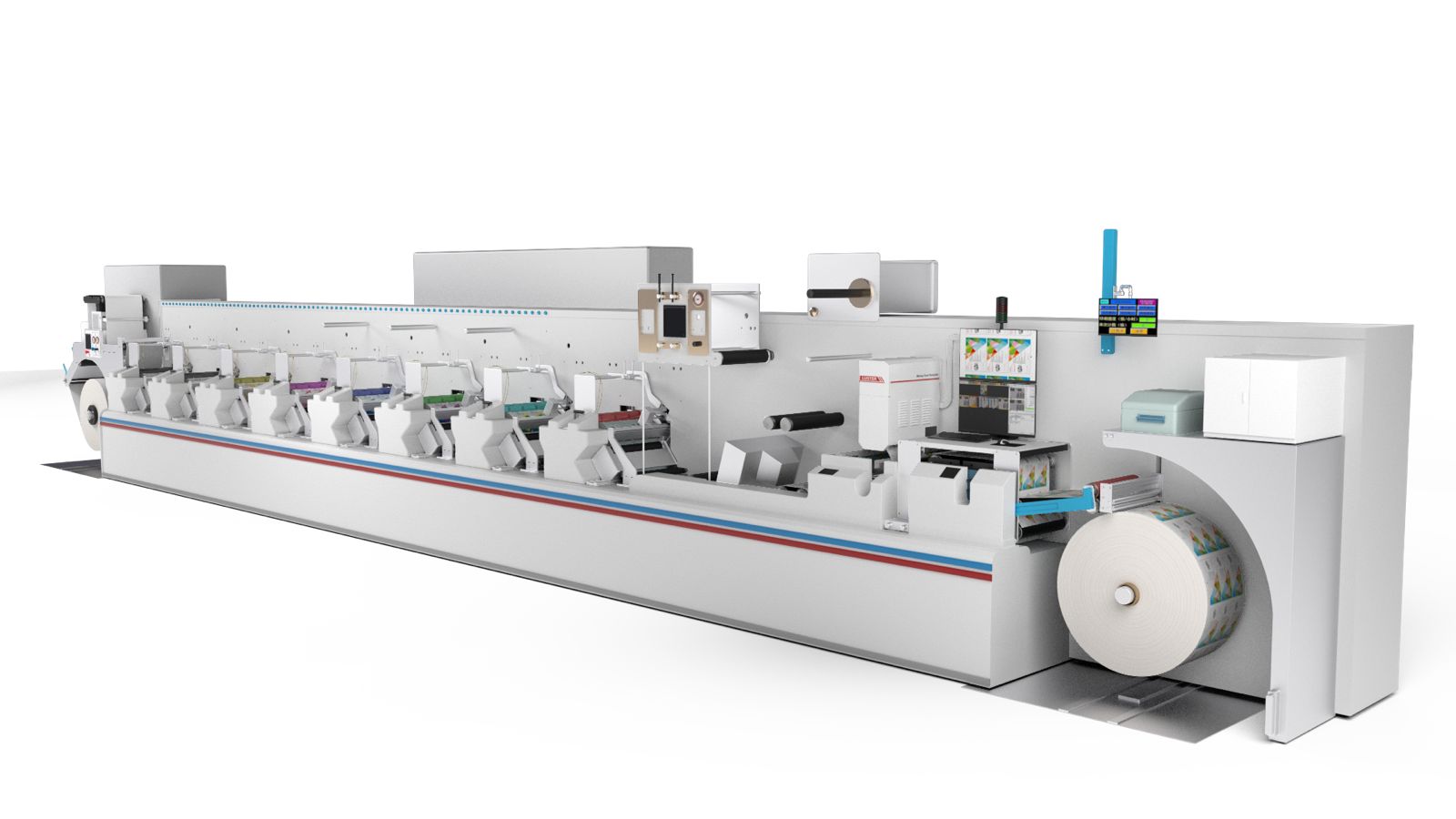

LabelHERO-P – Inline 100% Inspection System for Printing Presses

100% Quality Control, Inline & Real-Time

Designed for flexo, letterpress, and digital presses, the LabelHERO-P provides inline 100% inspection of labels and narrow-web applications.

Objective: waste reduction, lower production costs, and improved efficiency.

Key Strengths

Inspection Power

- Reliable detection of all defect types: missing print, spots, misregistration, color variation, die-cut/embossing errors, variable codes, etc.

- Compatible with all substrates, including transparent, metallic, and clear-on-clear.

Simplicity & Speed

- Zero waste at startup: only one reference image needed.

- Auto-setup, stored tolerances, intuitive interface for easy operator use.

Quality Analysis & Reporting

- Detailed report after each job: statistics, defect images, defect maps.

- Data archived for up to 6 months for continuous improvement.

All-in-One Control

- Real-time alarms & pixel-level monitoring.

- Integrated live web monitoring → no extra investment required.

Main Specifications

- Applications: cosmetics, food, beverages, pharma, wine & spirits, healthcare.

- Materials: opaque, transparent, metallic, clear-on-clear.

- Available widths: 330 mm, 450 mm, 520 mm (others on request).

- Max. speed: 200 m/min.

- Detected defects:

- Standard: spots, missing print, misregistration, cutting errors, color variations, etc.

- 3D (optional): bubbles, scratches, glue excess, varnish/lamination defects.

- Options: variable data inspection, color management, PDF comparison, workflow integration.

Sales Summary

The LabelHERO-P combines performance, simplicity, and versatility. It is the ideal solution for printers requiring zero-defect quality with a fast ROI.

LabelHERO-F – Offline Final Quality Inspection on Rewinders

100% End-of-Line Quality Control

Integrated with a rewinder, the LabelHERO-F ensures 100% quality inspection on finished rolls, providing a final check before delivery. This reduces customer rejections and complaints. With speeds up to 300 m/min, it optimizes production efficiency while detecting all printing, 3D, and variable data defects: missing print, spots, misregistration, broken text, color variation, bubbles, scratches, glue excess, etc.

LUSTER also supplies its own slitter rewinders to deliver a fully supported all-in-one platform.

Key Features

High Inspection Performance

- True 100% inspection of all printing and 3D defects (varnish, coating, lamination).

- Effective inspection of clear-on-clear, reflective, and other challenging labels.

Easy-to-Change Optical System

- Unique “drawer” design for quick change of light sources and cameras.

- Maximum adaptability to different substrates and products.

Advanced Integrated Functions

- Defect classification.

- Color management.

- Variable data inspection.

- PDF job proof.

Ease of Use

- Only one master image required.

- Inspection can start from meter zero.

- Automatic setup functions for simplified operation.

- Job data saved and re-usable for repeat runs.

Technical Specifications

- Applications: cosmetics & personal care, food, healthcare, beverages, wine & premium drinks, pharma, other narrow-web labels.

- Materials: opaque, transparent, reflective, clear-on-clear.

- Defects detected:

- Standard: spots, ink drops, missing print, misregistration, improper die-cut/stamping, broken text, color variation, foreign objects.

- 3D: bubbles, scratches, glue excess, varnish/coating errors.

- Available widths: 330 mm, 370 mm, 450 mm, 520 mm.

- Camera options: 4K & 8K color or mono line-scan cameras.

- Variable data inspection (optional):

- Barcodes (CODE128, CODE39, CODE93, EAN8/13, UPCA/E, ITF, CODABAR).

- 2D codes (QR, DataMatrix, PDF417).

- OCR, OCV, sequence numbers.

- Other modules:

- Light & sound alarm.

- Quality reports & analytics.

- Variable data inspection (optional).

- Color monitoring (optional).

- PDF job proof (optional).

- Workflow system.

Sales Summary:

The LabelHERO-F is the perfect solution for end-of-line quality assurance, ensuring 100% compliant rolls, reducing non-quality costs, and strengthening customer trust.

LabelTANK-220T – Table Top Inspection Rewinder

Developed and manufactured by LUSTER, the LabelTANK-220T series is an innovative all-in-one solution specifically designed for the inspection of short-run narrow web labels and electronic labels.

Key advantages:

- Simple operation.

- Accurate quality control.

- Short web path.

- Compact footprint.

It effectively replaces manual checking, increases productivity, and reduces waste during roll change and machine adjustment.

The rewinder is full-servo driven, ensuring precision, long lifetime, and low maintenance. Integrated with LUSTER’s inspection system and touch-screen HMI, it delivers intuitive use and precise defect stop.

Key Features

Compact Size & Short Web Path

- Dimensions approx. 1 m × 1 m × 1 m – easy installation, fast setup, space saving.

- 2 m web path – reduces operation time and material waste.

Fully Integrated Inspection

- 100% quality control with LUSTER’s system.

- Detects printing defects: spots, registration, color variation, missing print.

- Variable code defects.

Intuitive Use

- Touch-screen HMI.

- Inspection software & machine control on one screen.

- Clear, operator-friendly interface.

Multifunction Rewinding Solution

- Precise stop on defect.

- Bi-directional web path.

- Label & meter counting.

- “Rewinding – Inspection – Defect Removal – Delivery” in one cycle.

Technical Specifications

- Applications: beauty & personal care, food, healthcare, beverages, wine & premium drinks, pharma, other narrow-web labels.

- Defects: missing print, spots, ink spots, deckle edge, misregistration, stamping/die-cut errors, color variation.

- Inspection performance:

- Max. width: 220 mm

- Max. speed: 50 m/min

- Min. defect size: 0.1 mm

- Registration accuracy: 0.1 mm

- OS: Windows 10, 64-bit, English

- Table Top Rewinder:

- Width: 25–220 mm (core > 25 mm).

- Mechanical speed (without inspection): 200 m/min.

- Mandrels: 3” air expanding.

- Web path: 2 m.

- Dimensions: 1100 × 1100 × 1200 mm.

- Motors: full servo.

- Operation: bi-directional.

Sales Summary

The LabelTANK-220T is a compact, precise, and efficient solution for 100% quality inspection of short-run narrow-web labels. With its short web path, high accuracy (0.1 mm), and intuitive use, it ensures faster setup, less waste, and improved quality control.

LabelTANK-330 – Slitter Rewinder with 100% LUSTER Inspection

Slitter Rewinder Specifications

- Web width: 40–330 mm.

- Substrates: paper (100–320 µm), film (≥ 40 µm).

- Max. speed: 200 m/min.

- Max. unwind Ø: 700 mm.

- Max. rewind Ø: 450 mm (upper/lower).

- Mandrels: 3” air expanding.

- Rewind accuracy: ±0.2 mm.

- Web guiding: 2 BST units (unwind + rewind).

- Slitting: 10 shear blades (±0.2 mm).

- Defect stop accuracy: ±70 mm.

- Counting: meter & label (Leuze photoelectric sensor – Germany).

- Waste handling: nip roller & inspection table with clamps.

- Tension control: 15–120 N, ±5 N.

Components

- 4 servos (Inovance).

- Siemens HMI touch screen.

- Schneider electric components.

- NSK gears & bearings (Japan).

- Dimensions: 2340 × 1350 × 1200 mm.

- Weight: ~2.2 t.

- Power: 380 V, 50 Hz.

Inspection Vision System – LabelHERO-330-F-Mp8k1

- Max. inspection width: 330 mm.

- Max. inspection speed: 160 m/min.

- Min. defect size: 0.03 mm².

- Misregistration: ≥ 0.1 mm.

- Color deviation: ΔE ≥ 3.

- OS: Windows 10, multilingual (EN/FR/CN).

Defects Detected

- Standard: spots, ink spots, missing print, misregistration, die-cut/stamping errors, broken text, color variation, foreign objects.

- 3D: bubbles, scratches, glue excess, varnish/lamination defects.

Modules Included

- Vision Print 7 software (EN/FR/CN): general defects, die-cut, text, reports, ColorHERO.

- Imaging: 8K RGB line-scan camera, high-speed optics, LED + backlight.

- Processing: high-speed acquisition card, 2 TB industrial PC.

- Control: 2K encoder, LED/camera power, control cabinet.

- Add-ons:

- Dual monitors (32” HD + web viewer).

- Light/sound alarm.

- Industrial air conditioner.

- UPS.

- Standard tool kit.

Sales Summary

The LabelTANK-330 combines slitting, rewinding, and 100% inspection with 8K camera. With BST guiding, Inovance servos, and Vision Print 7 (with ColorHERO), it delivers extreme precision (0.03 mm²), color monitoring (ΔE), and high productivity (200 m/min).

Perfect for pharma, cosmetics, wine & spirits, and food markets.