- Home

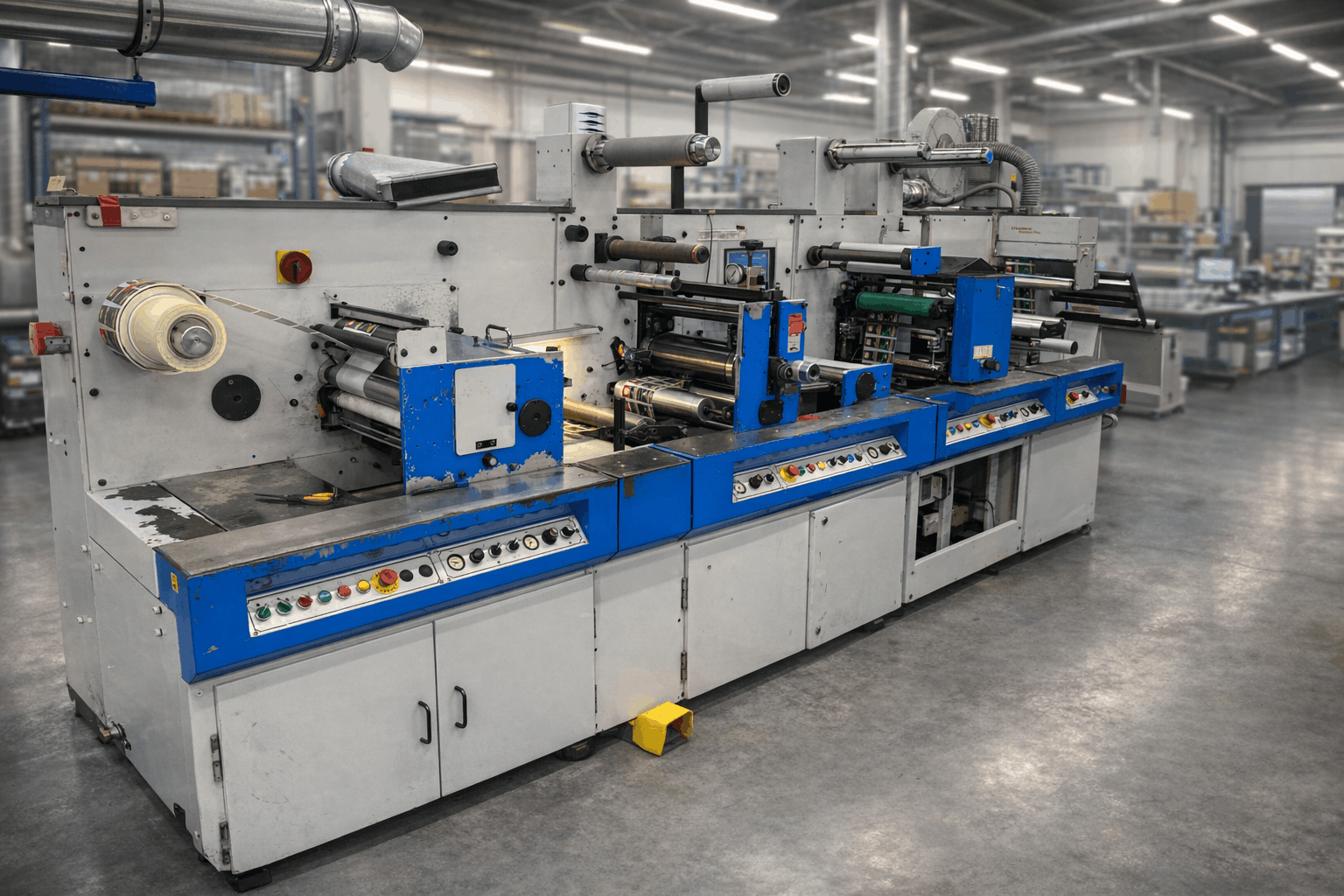

- SMAG Digital Converting Press

MG/108 – Galaxie Digitale (Year 2010)

This industrial printing machine is engineered for demanding production environments where stability, precision, and efficiency are essential. Its modular architecture allows the integration of multiple in-line processing stations, optimizing every stage from unwinding to final finishing.

General

- Web direction: Left to right

- Maximum unwind roll diameter: 850 mm

- Minimum web width: 100 mm

- Maximum web width: 350 mm

- Maximum speed: up to 35 m/min

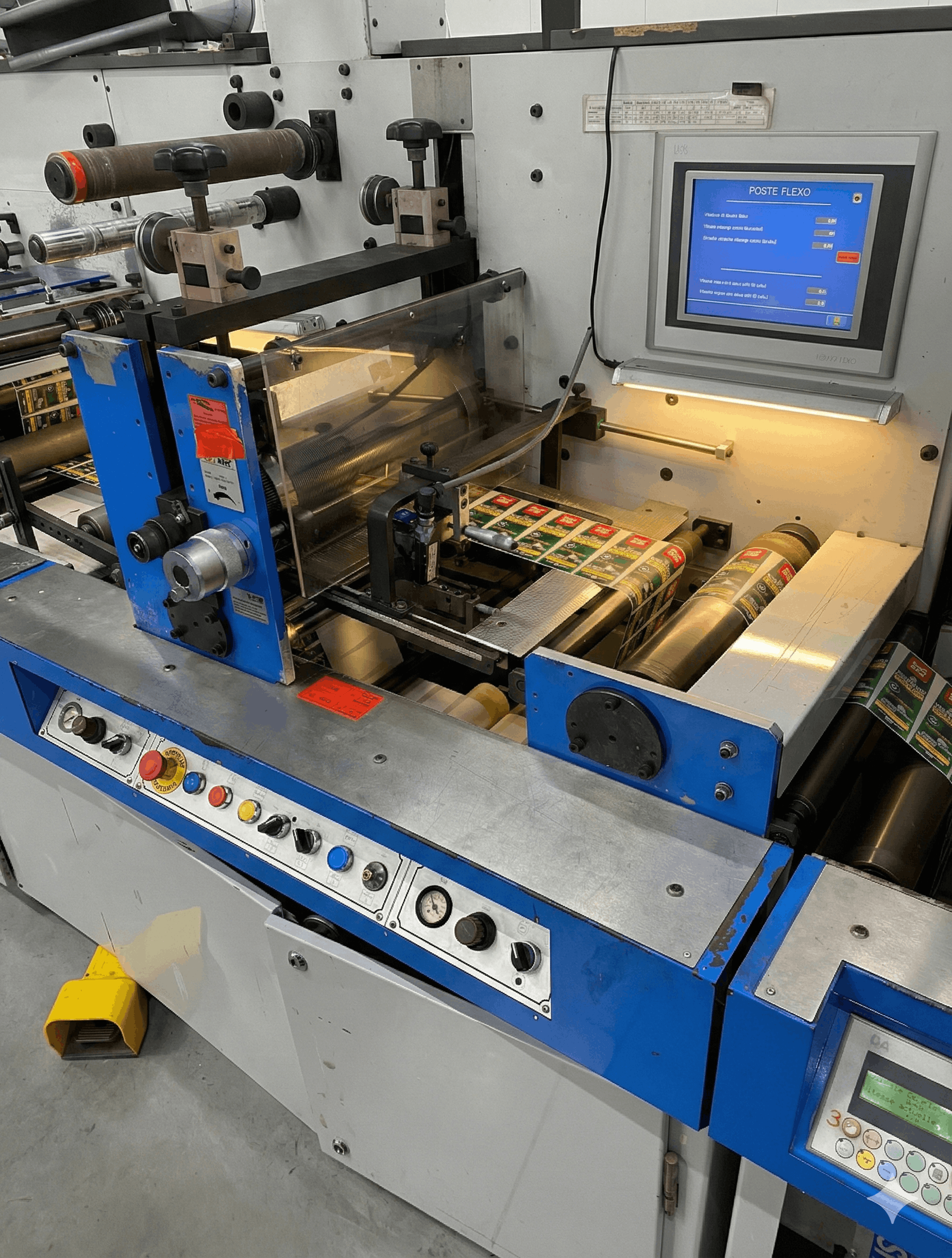

Flexo / Coating Unit

- Anilox: 120 lpi (or to be defined)

- Coating cylinder: 11” included

- Cross adjustment: ± 5 mm

- Printing plate thickness: 1.7 mm

- UV curing system: IST

Die-Cutting Unit

- Die-cut cylinder repeat supplied with press: 20”

- Minimum semi-rotary repeat: 100 mm

- Maximum semi-rotary repeat: 450 mm (with 20” cylinder)

- Die thickness: 0.44 mm

- Registration accuracy (full or semi-rotary): ± 0.15 mm

Waste & Rewinding

- Maximum waste rewind diameter: 500 mm

Rewinding

- Two mandrels – Alternative mode: 350 mm (optional diameters)

- Two mandrels – Simultaneous mode: 300 mm (optional diameters)

Slitting with Cassette System

- Maximum number of slitting blades: 10

- Minimum distance between blades: 12 mm

Utilities & Electrical

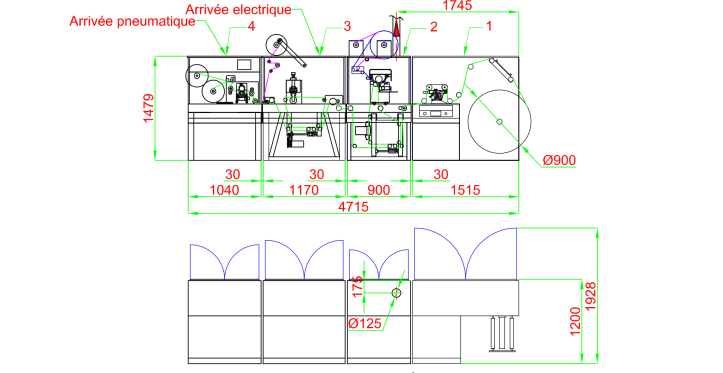

- Electrical power: Refer to line drawing

- Power supply: 400 V – 3 Phase + Earth

- Compressed air required: 6 bar

Dimensions & Weight

- Total length, width, height and weight: Refer to line drawing

- Unwinder with Web guide

- Corona treatment Vetaphone

- Semi rotary flexo unit with UV IST dryer

- Laminating / Cold foil station mounted on the flexo station

- Semi Rotary die cutting station + Waste rewinder with pressure arm

- Gap master integrated on the die station

- Slitting section with slitting cassette

- Dual rewinder

- Complete Inline Converting

From unwinding to final rewinding, all in a single pass. - Registration Accuracy ±0.15 mm

High precision in both full rotary and semi-rotary modes. - Flexo + UV IST

Semi-rotary flexographic unit with UV IST drying system for high-definition results.

- Integrated Cold Foil & Laminating

Added value without the need for external equipment. - Semi-Rotary Die Cutting with Gap Master

Full cutting control and fine registration adjustment. - Slitting System with Cassette

Up to 10 blades with a minimum spacing of 12 mm.

Key features

Maximum web width: 350 mm

Maximum speed: 35 m/min

Maximum unwind diameter: 850 mm

Dual rewinder (alternative or simultaneous mode)

Integrated Vetaphone corona treatment

Electrical system: 400V – 3 Phase

Industrial target

Self-adhesive label manufacturers

Printers seeking process integration

Companies requiring flexibility for short runs

Converters looking to add cold foil capabilities without expanding their production line

Sales listing version

Digital converting press with UV flexo, laminating, cold foil stamping, and semi-rotary die-cutting.

High precision, complete configuration, and ready for production.

Located in France.

Price: €37,000

Prices & Commercial Terms

- Price: 37 000 Euros

- Transportation: Ex Works – Actual user in France

- Installation: Not included (optional)

- Payment: 30% at order, 70% before shipment

- Warranty: None