- Home

- Hefeng Machinery Group

HeFeng Modules

II- HeFeng Modules (A → J)

A — Narrow-Web Corona Station

Technical Advantages

- HeFeng-Home-Set fine gap adjustment with electrode stop for system protection and repeatability.

- HV cable routed outside the ozone-exhaust area → improved anti-corrosion, longer electrode life.

- German-patented ceramic fin electrode ensures powerful, homogeneous, uniform treatment on plastics, aluminium, multilayer and metallised films, and paper.

- Minimal downtime for service/cleaning: HeFast-Change cassette, tool-less removal; all materials are ozone/corrosion-resistant.

- Open design with front inspection window for visual process control; one electrode length covers varying web widths.

- Easy cleaning of the electrode assembly and exhaust duct on the workbench.

- HeFast-Change cassette: simple maintenance, easy threading and fast changeovers; easy retrofit or new-line integration in any position.

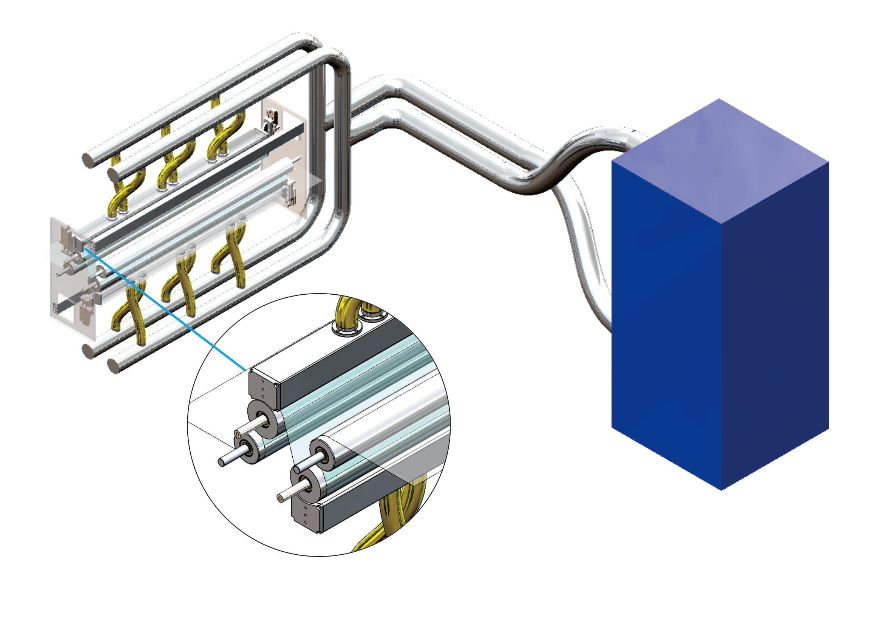

B — Wide-Web Corona Station

Technical Advantages

- New corona treater with adjustable gap and safety stop.

- HV cable separated from ozone exhaust area to avoid corrosion and extend service life.

- German fin ceramic electrode: powerful, homogeneous, uniform treatment on plastic films, aluminium foil, multilayer films, metallised films and paper.

- HeFast-Change cassette built from anti-oxidation/anti-corrosion materials: quick cleaning & maintenance without tools, reducing downtime.

- Open, pivoting electrode design makes web threading and material changes easier; auto open/close for thick substrates → higher efficiency.

C — Corona Generator

Technical Advantages

- Intelligent multi-function control with LCD touch screen.

- Four modes: local panel, corona station detection, remote, and automatic.

- Ozone fan start mode and stop-delay selectable.

- Multiple process-state alarms and equipment protection alarms.

- Multi-language UI; RS-485/Modbus support; Wi-Fi optional.

D — High-Performance Generator

Technical Advantages

- Power range 1–40 kW (multi-channel 2×1 kW to 4×40 kW)

- LC-Display or TFT panel; readout in Watts and/or corona dose.

- Advanced settings: thickness recognition, crosswise skip-treat (bag printing), speed-based power adaptation.

- Multi-language selection via display.

Options

- Power control analog or via fieldbus.

- Process monitoring with memory and USB.

- UL/CSA versions.

E — Ozone Converter

Technical Advantages

- Metal-oxide catalyst bed converts O₃ → O₂.

- High safety: non-flammable catalyst (no activated carbon).

- Long service life via dual pre-filters (dust/fibres) protecting the catalyst.

- Fast maintenance with exchangeable filter boxes.

- Size matched to exhaust flow of the corona system.

- Stainless-steel housing & piping, downstream exhaust fan, compact & durable design.

- Environmental protection by avoiding harmful emissions.

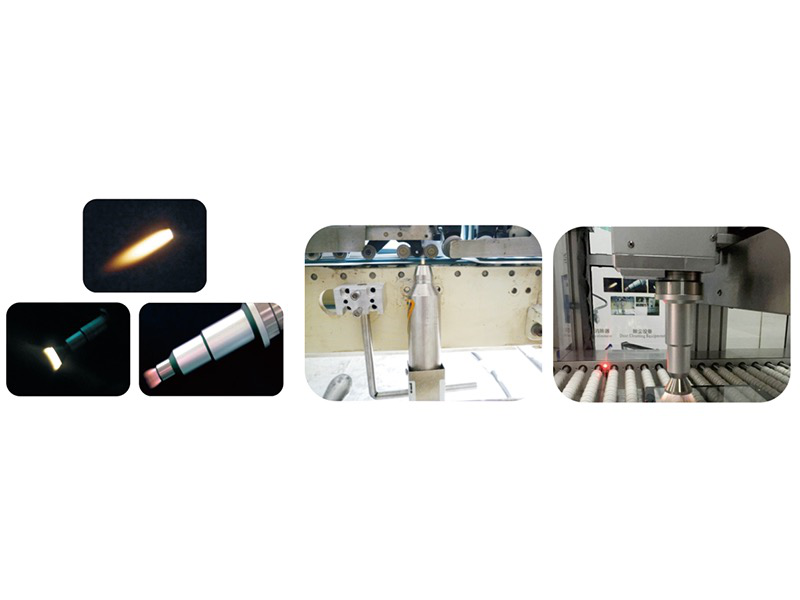

F — Plasma Treater

Technical Advantages

- Single- or double-sided web treatment; custom working widths

- Metering of gases and mixtures (N₂, CO₂, Ar, O₂/N₂, …).

- Ceramic-coated chill/backup roller with temperature control.

- Stainless electrode chamber rotatable 180° for easy servicing.

- Full enclosure with configurable slit systems.

- Cartridges for multi-point gas distribution; pressure controllers for accurate dosing.

- In-line port for gas-concentration measurement.

- Gas consumption and max speed depend on substrate/setup.

G — Contact Web Cleaner

Technical Advantages

- Designed for medium to wide webs; single or double-sided cleaning.

- Elastic cleaning roller with pneumatic loading for even pressure; removes dry, non-adhesive contaminants.

- Anti-stick paper (collector) with pneumatic open/close transfers particles from the roller for easy collection.

- Electrostatic neutralization to minimize re-contamination.

- Compact build: quick change of dust roller and paper, easy install & maintenance.

- Self-adhesive rollers (silicone/PU), mirror-smooth (< 2 μm), available in low/medium/high tack.

- Applications: coaters, printers, cleanrooms, films, labels/PSA, photovoltaic, pharma, etc.

H — High-Efficiency Non-Contact Surface Dust Removal

Principle & Advantages

- Non-contact cleaning to avoid surface damage.

- Optimized cavity design converts blower high-pressure airflow into a very high-velocity jet (ultrasonic-like effect) for efficient particle removal.

- Durable, easy to install/maintain, compact footprint.

- Stable performance without attenuation.

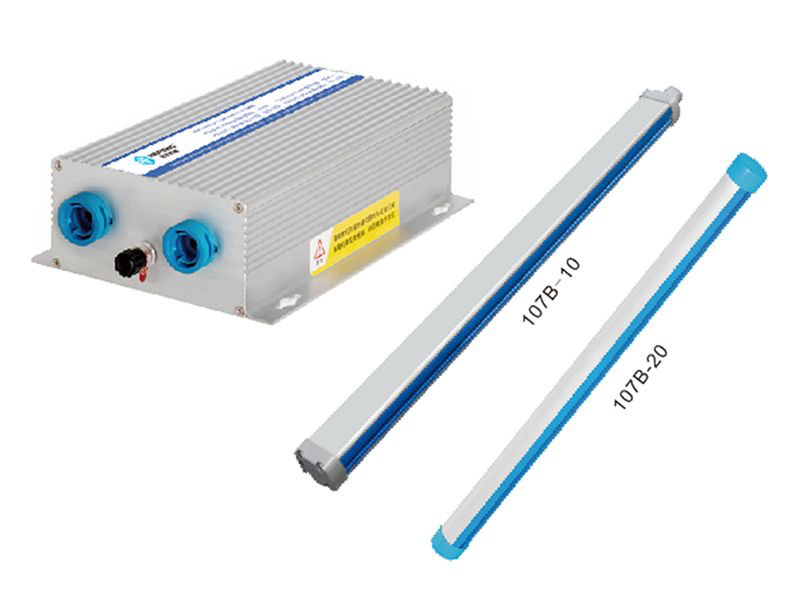

I — Electrostatic Eliminator (Ionizing Bar)

Applications

Plastic films, laminators, blown-film, coaters, printing, slitting, etc.

Technical Advantages

- Safe, shockless, touchable.

- Fast, thorough static elimination → fewer defects and reduced fire risk.

- Latest technology, CE certified.

- Bar length up to 4 m.

- Sealed aluminium body: moisture/dust-resistant; easy mounting.

J — Electrostatic Charging System

Technical Advantages

- High-voltage charging for electrostatic spraying, electrostatic bonding, dust removal, etc.

- Full electronic protection: short-circuit, over-voltage, over-current.

- Continuously adjustable output voltage/current with high-precision LED readout.

- Modular internal design, compact, stable for long-time operation.

- Soft-start control; local and remote operation.

- Customizable to user requirements.